The construction industry involves a wide range of activities, and most of them are not environmentally sustainable. Even the extraction of raw materials for conventional concrete—such as water, sand, gravel, limestone, and clay—represents a major environmental issue. However, the improper disposal of produced concrete is what causes the most significant negative impact on nature.

It is estimated that 10% of all material delivered to construction sites is wasted due to inefficiencies in the building process. Of this total waste, about 90% could be recycled. Unfortunately, in Brazil, only 5% of construction debris goes through any form of recycling. Recent studies have shown that concrete is a recyclable material. Therefore, with technological advancements, this scenario may change rapidly, making construction projects much more eco-friendly. Here’s how that could happen:

“On average, 2% to 3% of all concrete produced by a concrete plant ends up being returned and discarded as waste. Considering Brazil’s annual production of approximately 40 million m³ of ready-mix concrete, about 1 million m³ of waste is generated nationwide.”

– Engineer Luiz de Brito Prado Vieira, R&D consultant at Votorantim Cimentos, in Mapa da Obra.

Benefits of Recycling Concrete

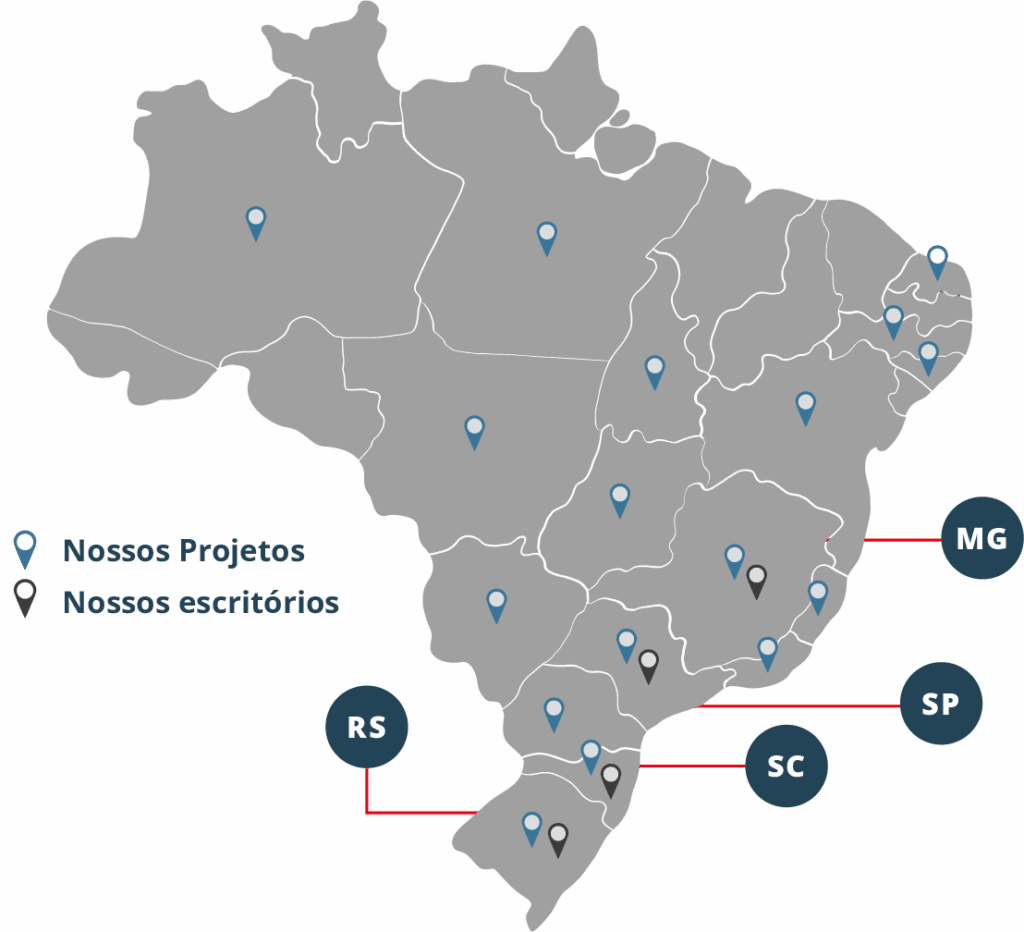

Concrete recycling is essentially the reuse of construction or demolition waste to partially or fully replace materials in a new concrete mix. Projects in São Paulo and Rio de Janeiro have already used recycled concrete. The benefits are numerous, especially for the environment. First, it reduces the use of natural resources. Second, it cuts down pollution in large urban centers by lowering the emission of harmful gases.

Recycled concrete is an excellent solution for managing construction waste and can be applied in many ways. For instance, the C&D waste recycling technique (Construction and Demolition waste, or RCD in Portuguese) allows certain materials to be used for road base layers. This aligns with research conducted by Daniel Simiele from São Paulo State University, who developed an alternative way to produce concrete. His method can be used for traffic-bearing road layers or interlocking paving blocks for sidewalks.

Types of Concrete That Can Be Recycled

Almost all types of concrete can be recycled, whether fresh or hardened. The most common are residuals from batching plants and C&D waste. The exceptions are easy to spot: concrete that is pigmented or contains contaminants like calcium sulfate, wood, or glass cannot be reused, as these elements may compromise the quality of the new mix. For structural elements, the dosage must be specified with extra care. In-depth studies are required to verify the real strength, durability, and crack resistance of the recycled mix.

How Concrete Recycling Works

There are specialized machines for recycling concrete. In Germany, scientists at the Building Physics Institute in Holzkirchen developed an electrodynamic fragmentation technique, where electric discharges are used to implode residual components. However, this is not the most common method used at recycling plants or job sites. Typically, the process involves crushing the material with jaw or impact crushers designed for this purpose. For small construction companies, acquiring and maintaining such equipment—and the space needed—is often the biggest challenge.

Concrete recycling centers must have not only the right equipment but also qualified technical personnel. They operate much like small mining facilities. Waste is transported to the plant by trucks, where it goes through conveyor belts and crushers to be broken down and separated.

Next, it passes through sieves and granulometric classifiers, where it is washed, sorted, and classified. The final product often resembles coarse sand and can be directly reused to produce new concrete. The recycled concrete aggregate is then mixed with sand, water, and cement to produce fresh concrete.

“Adding up to 25% of recycled aggregate to natural aggregate does not affect product quality.”

– Tarcísio de Paula Pinto, construction waste management consultant, in PiniWeb.

Sources: Arch Trends, Pensamento Verde, Mapa da Obra, PiniWeb